Common materials and bag types of multigrain bags (with common sizes)

2024-06-08

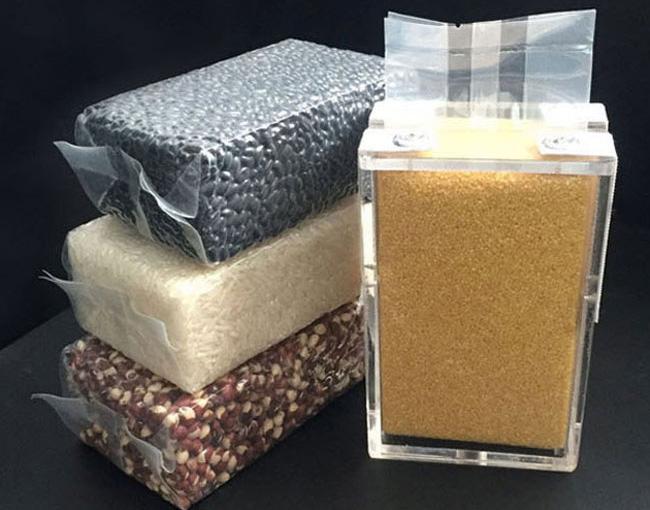

As a kind of natural food with high nutritional value, the packaging design of multigrain needs to meet the multiple needs of protecting products, extending shelf life and facilitating storage, transportation and sales. Therefore, the design of multi-grain bag is not only related to the choice of material, but also includes the design of bag type. This article will introduce the common materials and bag types of cereal bags, rice and millet bags in detail to help you understand how to choose the right packaging.

Multi-grain bags usually need to have good moisture resistance, gas resistance and heat resistance to maintain the freshness and quality of multi-grain. Therefore, the selected material needs to have these characteristics. The following is the common materials and composite methods of multi-grain bags.

Polyethylene (PE) : Low density polyethylene (LDPE) or linear low density polyethylene (LLDPE) is often used in the inner membrane because they have good moisture resistance and flexibility, suitable as a heat sealing layer.

Polypropylene (PP) : Polypropylene is also a common plastic material, with good mechanical properties, heat resistance and transparency. Its durability and strength are higher than polyethylene, so it is more suitable for the production of large bags of cereals. The gas barrier performance of polypropylene is slightly worse than that of polyethylene, but it can still meet the requirements of most cereals packaging.

Polyester (PET) : As an outer film, PET provides good mechanical strength and gas resistance, helping to protect grains from the external environment.

Nylon (PA) : Nylon as an outer film, provides excellent gas resistance and puncture resistance, suitable for cereals with high packaging strength requirements.

l Biaxial polypropylene (BOPP) : BOPP as an outer film, provides good transparency and mechanical strength, suitable for packaging that needs to show the appearance of multigrain.

Multi-grain vacuum bags generally have NY/PE, PET/PE, VMPET/NY/PE, PET/VMPET/PE, PET/VMPET/PE, PET/AL/NY/PE, etc., can be customized with various materials. The multi-grain moisture-proof bag is to prevent corrosion, deterioration, mildew and other reasons after food encounters water. This effectively protects the shelf life of the food.

In the choice of bag type, three-side sealing, back sealing bag, self-supporting bag, etc., are common choices.

Back sealing belt folding: the front printing pattern of the back sealing bag is complete, the folding design makes the bag more beautiful, increases the printing surface of the bag, and improves the space utilization rate. The back sealing bag is sealed on the back, the pressure bearing capacity of both sides of the bag is stronger, and the possibility of packaging damage is greatly reduced. The hem increases the capacity of the bag.

Self-supporting zipper bags: Self-supporting zipper bags are an increasingly popular choice in modern packaging design, especially for small packages of multigrain. This bag type has a bottom extension that allows it to stand without any support, making it ideal for shelf display. They are usually equipped with a top zipper closure, which is convenient for consumers to open and close repeatedly, maintaining the freshness of the multi-grain.

l Three-sided seal: The three-sided seal has high space utilization rate and good air tightness, which can ensure the freshness of products and reduce the loss of nutrients. Three-side sealing bag can increase zipper, hanging hole, etc., more convenient to hang on the shelf display. Commonly used as the inner packaging of cereals, the price is lower under the same specifications, and the cost performance is high. In addition, the outer packaging bag will generally add a portable button, the color and size are determined according to the color and size of the packaging bag.

Window bags: In order to increase the appeal of packaging and allow consumers to see the product inside the package, manufacturers often design one or more Windows in multigrain bags. These Windows can be transparent plastic or film materials, allowing consumers to visually see the interior of the grain, increasing the lure of the product. The window bag can be a flat bottom standing bag, side pleated bag or self-supporting zipper bag variant.

In addition, vacuum packaging is currently the mainstream packaging method of high-end products, vacuum packaging can effectively prevent the oxidation of grains and grains, extend the shelf life. The vacuum packaging bag has strong air isolation performance, waterproof, moisture-proof and anti-oxidation, and can also play a certain protective role in a humid environment. At the same time, vacuum packaging can also reduce the number of bacteria in the bag and improve food safety. In addition, vacuum packaging independent molding, visually more beautiful, advanced, virtually enhance the grade of grains.

| Multigrain bag common specification table | ||

| Weight (kg) | Dimension (mm) | Thickness (um) |

| 2.5 | 270*400 | 130-150 |

| 5 | 300*500or320*520 | 160-180 |

| 10 | 350*600 | 190-230 |

| 15 | 400*650 | 220-260 |

| 25 | 450*770 | 250 or more |

Based on the principle of combining practicality and aesthetics, the design of multi-grain bag ensures the long-term quality of multi-grain while also considering the convenience of use and shopping experience of consumers. In addition, there is an increasing emphasis on the use of environmentally friendly materials, such as biodegradable plastics and recyclable materials. When designing multigrain bags, manufacturers and brands should consider product characteristics, market positioning, sales channels and consumer preferences, choose the right bag type and material, and create both practical and attractive packaging.

-

2024-09-19

-

2024-09-09

-

2024-08-21

-

2024-08-16