Why are degradable plastic bags PBAT+PLA as raw materials?

2024-09-24

Question: Why are degradable plastic bags made of PBAT+PLA?

Good Answer:

With the gradual implementation of the plastic bag restriction order, major supermarkets have actively responded to the national policy and replaced the degradable plastic bags that meet the plastic limit policy. But I do not know whether we have observed that in the formula of degradable plastic bags, almost all can see PBAT+PLA, which advantages of this system in making bags?

First of all, polyadipic acid/butylene terephthalate (PBAT) is a degradable polyester, which has good mechanical properties of PBT polyester, but also good tensile and ductility of aliphatic polyester, and the most important is that it has good biodegradation ability, which can be reduced to water and carbon dioxide under certain conditions.

Polylactic acid (PLA) is currently the most widely used biodegradable plastic, biodegradable, is a powerful alternative to traditional plastics.

Degradable plastic bags, the use of PBAT+PLA, because the two can complement each other to meet the application performance of plastic bags. First of all, in terms of mechanical properties, because the melt blending of PBAT+PLA is a physical modification method, when the two reach a specific proportion, both tensile strength and elongation at break will be significantly improved. Secondly, the degradation performance can also be improved.

Related knowledge development:

So what are the advantages of PBAT+PLA+St?

01, starch

Starch plants are widely distributed in fruits or plants, roots or leaves. There are up to hundreds of millions of tons of starch produced worldwide each year, which is a lot of can

A renewable, biodegradable resource that has the advantage of being widely available and inexpensive. However, due to the microcrystalline and granular structure of natural starch, it does not have thermoplastic processing properties, and needs to be transformed into thermoplastic starch, so as to have thermoplastic processing properties.

Amylopectin structure

Amylose structure

02. PBAT

Polyadipic acid/butylene terephthalate (PBAT) is a kind of degradable polyester which has attracted much attention. It has not only good mechanical properties of PBT polyester, but also good stretchability and ductility of aliphatic polyester, and can be decomposed into water and carbon dioxide under natural conditions.

However, the high price of the material limits its application in the market; Therefore, its inexpensive, degradable starch and PBAT blend is a good choice.

03. PLA

PLA (polylactic acid) is also known as polylactic acid, the production process of polylactic acid is pollution-free, and the product can be biodegradable, to achieve the cycle in nature, so it is an ideal green polymer material, is one of the representatives of bio-based biodegradable plastics.

However, in practical applications, there are also many shortcomings: PLA toughness is relatively poor, lack of elasticity and flexibility, hard texture and brittle large solution strength is relatively low, crystallization rate is too slow, etc., the above defects limit its application in many aspects.

The chemical structure of PLA contains a large number of ester bonds, resulting in poor hydrophilicity and degradation rate need to be controlled. Moreover, the high price of PLA has increased the cost of raw materials and limited its commercial promotion. Therefore, PLA was modified in view of the above shortcomings.

PBAT has soft texture, strong ductility and short degradation period. The texture of PLA is brittle, the toughness is poor, the degradation period is long, so the mixed use of the two is an excellent method to improve the performance.

04. Introduction of PBAT/PLA materials

【 Compatibility 】

The melt blending of PBAT and PLA is a kind of physical modification technique, and its main point is to require good compatibility between the two. However, the solubility of PBAT and PLA is very different, so the compatibility is poor and it is difficult to mix evenly.

Improving the compatibility between PBAT and PLA is the primary problem. It is necessary to add one or more compatibilizers in the blending process to improve the adhesion of PBAT and PLA interface. Commonly used compatibilizers are plasticizer, reactive compatibilizer, ductile polymer.

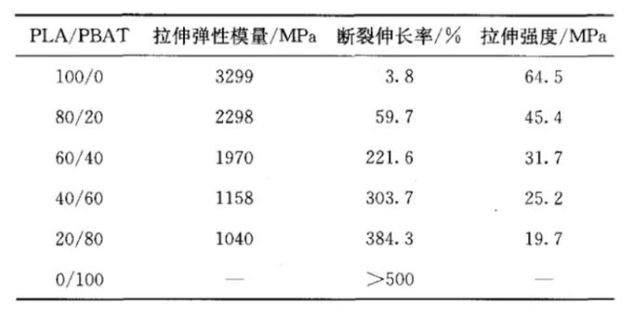

【 Mechanical properties 】

PLA and PBAT have complementary properties, so there must be a good mass ratio of comprehensive performance.

1. The proportion of PLA increased to 40% as node, the tensile strength of the material first decreased and then increased, and the elongation at break first decreased significantly and then remained stable.

2, if the PLA content is greater than 70%, the material is too brittle to blow into film. Therefore, the ratio of PLA to PBAT should be maintained at about 1:1 according to the additives.

【 Degradation performance 】

The initial reaction of material degradation is the hydrolysis of water molecules. If it is a separate PBAT material, due to the existence of rigid ester bonds in the molecular structure, water molecules are difficult to enter and therefore not easy to degrade. The PLA molecule is easily invaded by water to degrade internally, so the higher the PLA content, the faster the material degradation rate.

-

2024-10-10

-

2024-10-09

-

2024-10-08

-

2024-09-30